Why it matters

Using defective cables in your building is dangerous and potentially very costly. Contractors can minimise their risk and the liability of installing defective cable by using an ACI recognised product. Upholding Australian Standards for electrical cables is of paramount importance.

Let’s examine recent examples non-compliant and dangerous cables sold into the Australian market: Infinity Pty Ltd, Olsent Pty Ltd, and ECables Pty Ltd cables.

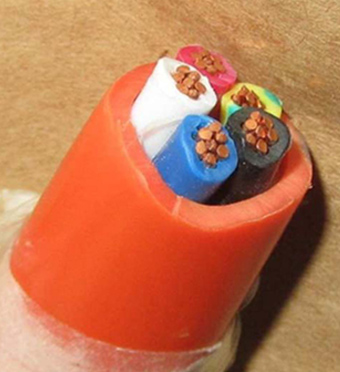

Image: This cable is rated to run at 110 degrees Celsius. However, when we ran tests at this temperature, the insulation melted.

ECables’ Faulty Cable – Case Study

“Testing showed that the cable was non-compliant due to a manufacturing fault that identified the cable’s insulation sheath had not been cross-linked. Due to the non-cross linking of the insulation, the cable’s mechanical properties are reduced with the increase of temperature. This can allow access to live parts if the cable is subject to pressure like cable ties, the weight of other cables, or accidental penetration from foreign objects.”

Source: Energy Safe Victoria

All buildings with ECables cable installed received a circuit protection rating downgrade. They were also required to carry out a series of extra measures to ensure the insulation covering did not melt off the cable (including reducing ambient temperature where they are installed, regular inspections, etc). If these additional safety measures could not be completed, the cable needed to be removed. Naturally, as these cables are usually installed in ‘hidden’ areas such as inside walls, roof cavities, and riser shafts, performing the mitigating measures for ECables is cost-prohibitive and not practical.

The risk of liability for an installer who inadvertently installed faulty ECables is huge. It would be costly to leave in place and it is costly to remove.

Image: The insulation snaps easily when bent after being subjected to the mandatory ageing test required for compliance with Australian Standards.

Infinity and Olsent non-compliant cable – Case Study

Infinity and Olsent cable is subject to ACCC mandatory recall.

“Tests have shown that the cable insulation may become prematurely brittle, which could cause fires or electric shock if the cables were then disturbed, such as by human or animal activity. While the risk is not imminent, people need to be aware and take careful steps to manage the risk in coming years.”

Source: Energy Safe Victoria

If a cable is dangerous and must be replaced it is an expensive and difficult task. Under Australian Consumer Law those costs are shouldered by the installer.